Introduction

In manufacturing’s high-speed landscape, precision, speed, and real-time data are essential. Ensuring production goals are met, quality remains high, and downtime is minimized. From receiving materials to shipping finished products, every step must be streamlined and transparent.

Advanced scanning devices, handheld scanners, mobile computers, ring scanners, scan engines, and electronic shelf labels (ESLs), are transforming operations by automating data capture, increasing visibility, and enabling fast, coordinated workflows.

The challenges in manufacturing workflows

Manufacturers face a variety of operational challenges, including:

- Locating or tracking materials quickly on the work floor

- Manual data entry leading to errors in production

- Mislabeling causing costly quality issues

- Poor coordination among production, quality, and logistics teams

- Growing demand for real-time insight into production and inventory

How scanning technologies upgrade manufacturing processes

Advanced scanning solutions help manufacturers achieve faster throughput, reduce waste, and maintain product quality. By digitizing and automating data capture at every stage, from goods receiving to assembly and packing, scanning technologies improve operational accuracy and efficiency.

Handheld Scanner

- Rapidly identify and verify raw materials, work-in-progress, and finished goods

- Reduce errors in labeling, picking, and packing processes

- Speed up receiving and dispatch operations

- Easy to deploy across warehouse and production areas

Mobile Computer

- Combine scanning with direct ERP, MES, or WMS integration

- Provide operators and supervisors with instant access to production schedules, inventory counts, and order status

- Improve coordination between shop floor and back-office teams

Benefits of Implementing Advanced Scanning Solutions

- Faster throughput: Accelerate production and shipping timelines

- Higher accuracy: Reduce mislabeling and picking errors

- Improved productivity: Minimize wasted motion and downtime

- Better quality control: Capture data at every stage for full traceability

- Real-time data: Maintain live visibility of production and inventory

- Scalable deployment: Adapt to different manufacturing environments and production volumes

How ESL transforms manufacturing workflows

Electronic Shelf Labels (ESLs) are revolutionizing work floor communication and material handling. By providing real-time updates for bin locations, assembly instructions, and production priorities, ESLs minimize confusion, reduce paperwork, and help keep production on track. ESLs also support pick-to-light applications, ensuring operators can quickly locate and select the correct parts for each job, improving both speed and accuracy.

Electronic Shelf Labels

- Display live material counts and bin assignments

- Update assembly instructions and job sequences instantly

- Reduce errors in part selection and assembly processes

- Improve coordination between production, maintenance, and logistics teams

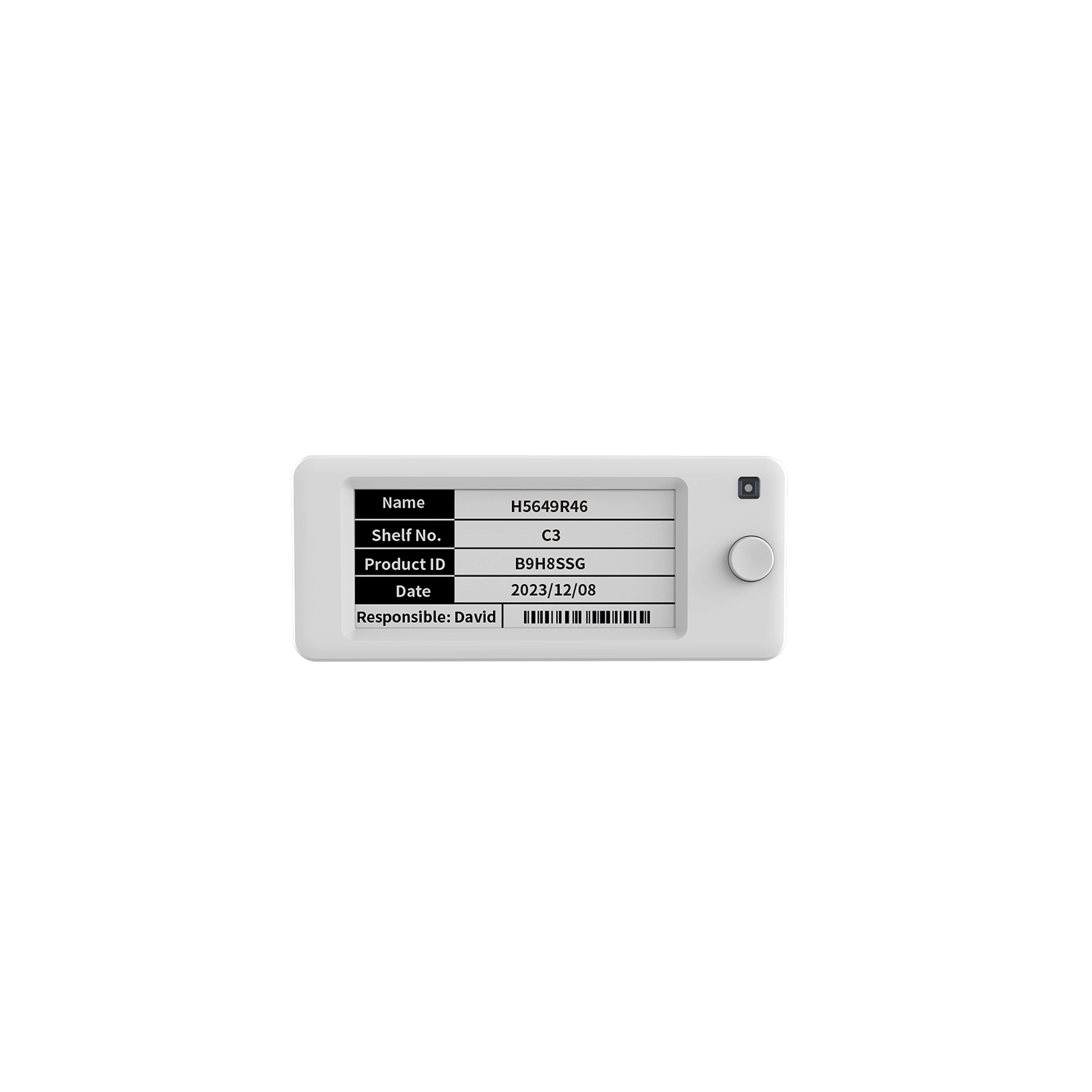

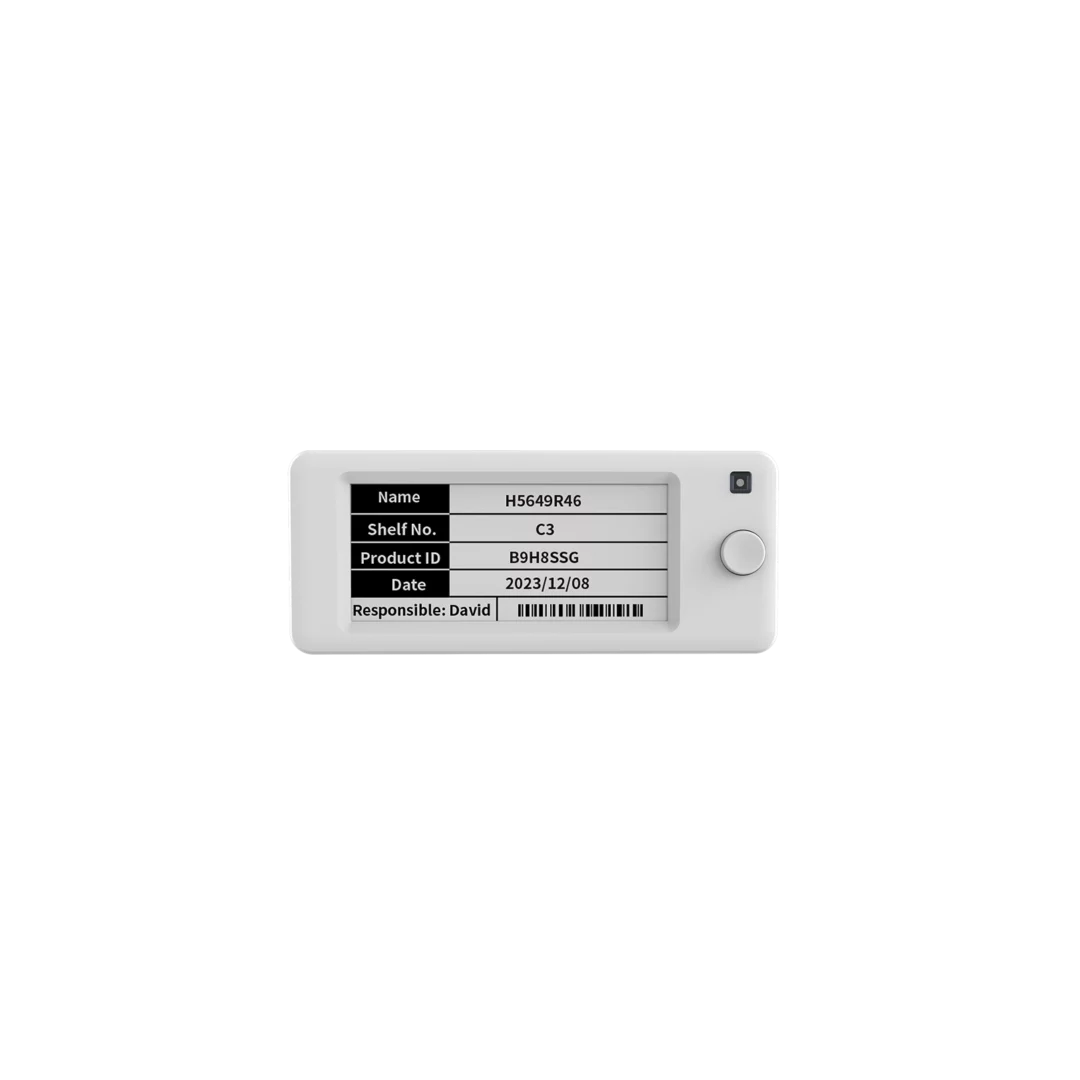

Opticon ESL

- Compact and lightweight design for prolonged use

- Wireless connectivity for instant updates

- Integrated scanning for part verification and workflow confirmation

- Long battery life for uninterrupted shifts

Benefits of implementing esl solutions

- Real-time accuracy: Always up-to-date material and production data

- Labor efficiency: Reduce manual label changes and paperwork

- Error prevention: Minimize mistakes in part picking and assembly

- Improved workflow coordination: Keep all teams aligned with the latest priorities

- Sustainability: Reduce paper waste from printed work orders and labels

- Increased output: Speed up production and assembly with clear, dynamic instructions

By smartly integrating handheld, mobile, stationary scanning systems, and ESLs, manufacturers unlock a leaner, more agile, and data-driven production environment. The result? Higher productivity, fewer errors, elevated traceability, and responsive workflows, all keys to thriving in today’s competitive manufacturing landscape.

Contact

"*" indicates required fields