Laser based engines

How does it work

Laser engines are linear (1D) scan modules. They consist of a small semiconductor laser, an optical system with a moving mirror to make the laser line, a photodiode to process the reflected laser light, electronics to amplify the signal from the photodiode and a processor that decodes the signal and outputs the decoded data via a serial interface or USB.

The scan module has its laser aimed towards a vibrating or rotating mirror that turns the dot into a line. This line is aimed at a target barcode which reflects the light back to the scan engine. The same mirror that is used to make the laser line, is then used to aim the reflected laser light to a photodetector. The output from this detector is then amplified, filtered, and fed to a microprocessor which decodes the signal.

A schematic overview of this process is shown below:

![]()

The construction of a laser module is shown below where one of our modules is shown without the electronics. This makes it easy to understand the optics involved. Of course, the construction varies between our laser modules but the basics are the same.

Advantages of laser modules are:

- Cheap due to the relatively small required processing power

- Can read high-resolution barcode

- Large depth of field

- Low power consumption

- Fast scan rate (on certain models)

Disadvantages of Laser modules are:

- Cannot read from an LCD screen

- Cannot read 2D codes

Quick Scan

Laser based engines

Filter products

1D or 2D

Product Communication interface

Product Selector

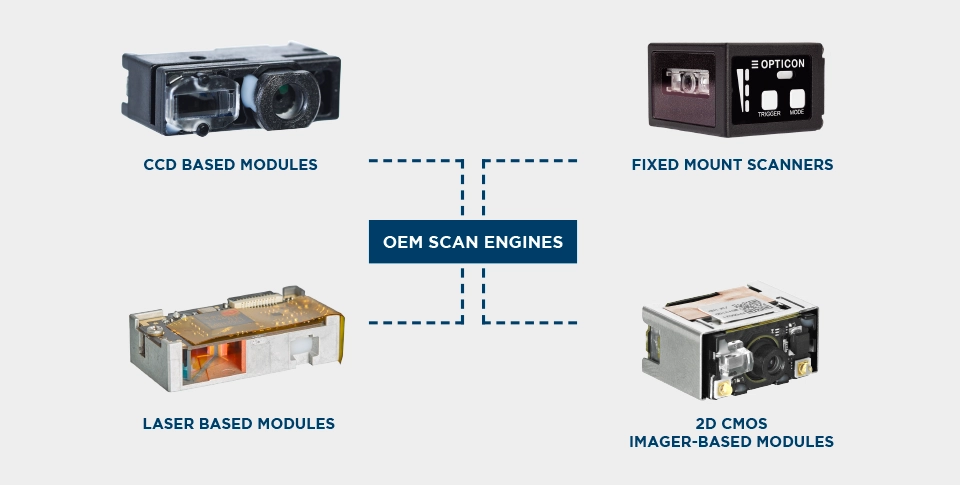

Which OEM scanning product is best for you?

Use our product selector to explore which OEM Module or Fixed mount scanner is right for you.